Its all in the design..

- Jun 24, 2022

- 3 min read

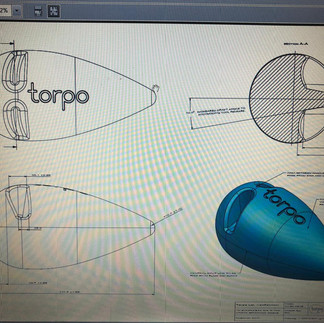

The Torpo® T500 won the prestigious International Design Award Bronze medal in 2021. This was the culmination of many years of design work, pool testing, scientific study, ergonomic analysis and hydrodynamic theory. The award sits alongside IDA awards to big name products and brands such as the Maserati MC20 car, Adidas, Google, Twitter, BP, Nespresso, Mercedes-Benz and Facebook.

Product design often starts on the drawing board, but it can also start as an idea, a way to solve a problem. Design Award criteria stipulate that the products must demonstrate not only innovative design but the design problem and the way that the product 'solves' this. In the case of Torpo® and the T500, the problem was the ability to teach swim kicking drills with a piece of equipment which allows free rotation in the lateral plane.

Why is this important?

Because freestyle swimming requires lateral rotation for an efficient stroke. Yet decades of swim training kickboards and generations of swimmers have learnt to swim and kick with a flat board (the traditional flat kickboard) which tries to stop rotation. Whilst this is important and necessary for young children and new swimmers who need help with their stability, it is not necessary and actually a hindrance for anyone who can swim freestyle (front crawl) unaided.

How did the idea come about?

As an experienced swim teacher in the UK, the founder of Torpo® tried to find equipment to help rotation whilst kick training, while still maintaining longitudinal stability. After over 30 years of a career in military and civil aviation, the founder had much experience in the dynamic effect of aerodynamics. This was translated to hydrodynamics and conjoined with experience as a swim teacher and coach.

Hence the use of a ball, such as a water polo ball, did not work. This provided good lateral instability, obviously, due to its spherical shape, yet its equal longitudinal instability was a hindrance to learning. In addition, the air within the ball meant it sat too high in the water for successful drills. A tied 'Woggle' float worked slightly better, as it provided the lateral instability and longitudinal stability that was required whilst also having good surfaces to hold onto. But it was still incongruous in shape and created much drag.

What were the early design stages?

Sketches were refined to detailed drawings and 3D images. This process was iterative, with many changes and adjustments throughout. Eventually prototypes were constructed using a CNC machine, with hard foam sections cut to the computer-controlled design. The prototypes were then pool tested.

CNC machining created the early foam prototypes. Later prototypes were heat moulded in Dorset UK, before final production using injection moulded foam in Italy. This process allowed the desired quality although due to the size and mass of the Torpo, it had to be made in two parts.

Swimming pool, training pool and open water testing was completed with constant feedback to the design process. Throughout these stages we worked with an experienced patent lawyer to refine the 'claims' on which the patent is based. The Torpo® T500 achieved UK registered design status in 2021. Thanks to Stuart Hacker and the Swimcube team for the use of their fantastic training facility in Northampton. Such high level feedback allowed honing of the Torpo® T500 to the final model.

What is next?

In the pipeline is the Junior Torpo, aimed at swimmers of a younger age (8+) which will be smaller and lighter. In addition we are working oan Elite Torpo which is aimed at experienced swimmers focusing on specific drills, such as one handed stroke and kick.

The end result, a Bronze medal (and trophy!) from the International Design Awards.

Comments